Product Description

CNC Machined Parts Precision Metal Parts Motorcycle Parts

Product Description

1. Precision CNC machining parts strictly follow customers’ drawing, packing, and quality requirements.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

Detailed Photos

Product Parameters

Our advantage of cnc machining:

| Business Type | Beyond the Manufacturer and strong organized ability in the industrial |

| Benefits | 1. Deeper industrial experience at CNC machining parts service for more than 10-years,our customer’s requirement is our 1st priority. 2. 2D or 3D files is available; 3. We trust the quality priority and we insist the good quality should be based on the customers’ satisfied; 4. Without any MOQ requirement; 5.Faster delivery time; 6. Customized size and specification /OEM available 7. Near ZheJiang Port |

The material

| Materials Accept |

Stainless Steel | SS201, SS303, SS304, SS316 etc. |

| Steel | Q235, 20#, 45#, | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) | |

| Iron | 1213, 12L14,1215 etc. | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Plastic | ABS,POM,PC(Poly-Carbonate),PC+GF,PA(nylon),PA+GF, PMMA(acrylic)PEEK,PEI etc) |

Packaging & Shipping

- We prefer DHL or TNT express or other air freight between 1kg-100kg.

- we prefer sea freight more than 100kg or more than 1CBM

- As per customized specifications.

Company Profile

About us

HangZhou CHINAMFG Technology Co.,Ltd is located in HangZhou City, ZheJiang Province, Which closed the ZheJiang .The Emitech Technology is mainly engaged in the CNC Machinery Industrial Service for 15 years. Our Parts are sold to Europe, America, Japan, South Korea and China in various kinds of industrial.At present, Our company has CNC Turning machines and CNC centers and equip with professional quality and testing instruments.We have full OEM Experience from worldwide, providing them with One-stop solutions for a broad range of applications.We look CHINAMFG to cooperating with you!

Our Advantages

1. Precision CNC machining parts strictly follow customer’s drawing,packing and quality requirement.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

After Sales Service

Factory Supply High Demand aluminum machining parts factory

We usually provide 12 Months repair service. If our duty, we will respond to send the new parts.

Our Service

| Our Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per the customer’s request |

| Shipment Terms |

1)We prefer DHL or TNT express or other air freight between 1kg-100kg. 2) we prefer sea freight more than 100kg or more than 1CBM |

| Note | The CNC machining parts are usually custom-made based on the customer’s drawings and samples. So we need the Down Payment |

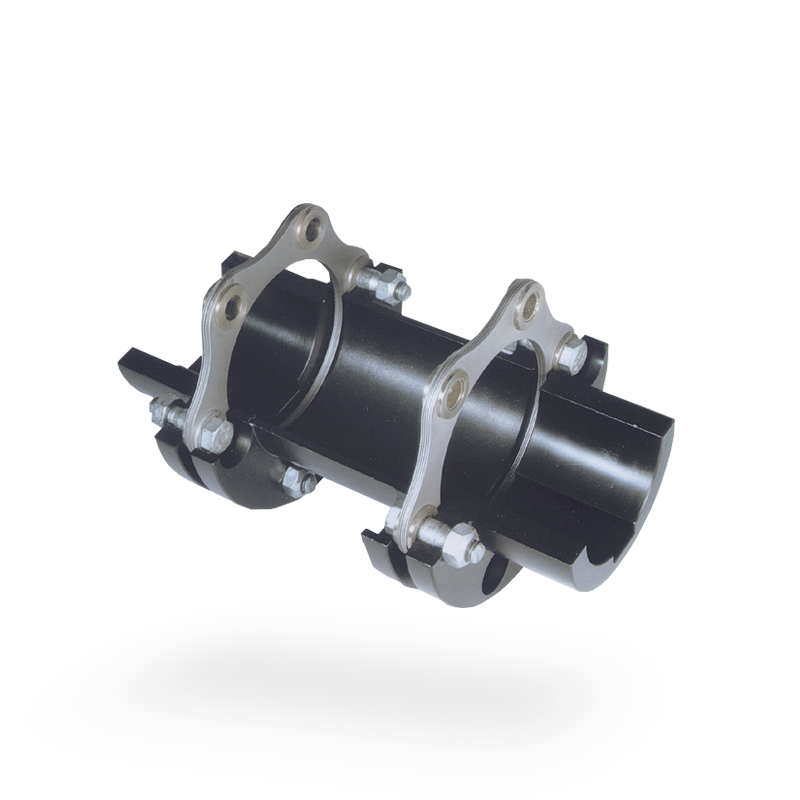

Comparison of Disc Couplings with Other Coupling Types

When comparing disc couplings with other coupling types like jaw couplings and elastomeric couplings, several factors come into play:

- Flexibility: Disc couplings offer high flexibility and misalignment compensation, similar to elastomeric couplings, making them suitable for applications with angular, axial, and parallel misalignment.

- Torsional Stiffness: Jaw couplings are known for their high torsional stiffness, which is suitable for precision applications. Disc couplings offer a balance between flexibility and stiffness.

- Misalignment Compensation: Disc couplings excel in accommodating misalignment, whereas elastomeric couplings and jaw couplings are better suited for lower degrees of misalignment.

- Vibration Damping: Elastomeric couplings provide excellent vibration damping due to their rubber elements. Disc couplings can also dampen vibrations to some extent.

- Compactness: Jaw couplings and elastomeric couplings are relatively compact, making them suitable for space-constrained applications. Disc couplings are larger in size but offer higher torque capacity.

- Torque Capacity: Disc couplings generally have higher torque capacity compared to elastomeric couplings and jaw couplings.

- Installation and Maintenance: Disc couplings and elastomeric couplings are typically easier to install and require less maintenance compared to jaw couplings.

- Material Options: All three coupling types are available in various materials, allowing for compatibility with different environments.

The choice between disc couplings, jaw couplings, and elastomeric couplings depends on the specific requirements of the application, including torque, misalignment, vibration, and stiffness considerations. Each coupling type has its strengths, and selecting the right one involves evaluating these factors to achieve optimal performance and reliability.

Recent Advancements in Disc Coupling Design

Disc coupling technology has seen continuous advancements to enhance performance, reliability, and adaptability to various applications. Some recent innovations in disc coupling design include:

- Material Enhancements: The development of new materials, such as advanced alloys and composite materials, has improved coupling durability, corrosion resistance, and overall lifespan.

- Flexible Disc Profiles: Innovative disc profiles are designed to optimize flexibility while maintaining torque transmission capabilities, allowing for better misalignment compensation and shock absorption.

- Modular Designs: Modular disc coupling systems offer flexibility in adapting to different torque and misalignment requirements, making them versatile for a wide range of applications.

- Enhanced Torsional Stiffness: Some designs focus on achieving higher torsional stiffness, ensuring accurate torque transmission and responsiveness even in demanding conditions.

- Smart Couplings: Integration of sensor technology enables real-time monitoring of coupling performance, allowing for predictive maintenance and reducing downtime.

These advancements are driven by the increasing demands of modern machinery and the need for higher efficiency, reduced maintenance, and improved overall system performance. Engineers and manufacturers are continually exploring new ways to optimize disc coupling design for a variety of industries and applications.

Types of Disc Couplings for Specific Uses

Disc couplings come in various designs and configurations, each tailored to specific use cases and requirements. Here are some different types of disc couplings designed for specific applications:

- Single Disc Couplings: These couplings consist of two hubs and a single flexible disc element. They are suitable for applications where angular misalignment compensation is the primary requirement.

- Double Disc Couplings: These couplings include two flexible disc elements and three hubs. They provide higher torsional flexibility and axial movement absorption, making them suitable for more demanding applications.

- Spacer Disc Couplings: Spacer disc couplings incorporate a spacer between the flexible disc elements. This design allows for greater axial movement and misalignment compensation.

- Close-Coupled Disc Couplings: These couplings have a compact design with minimal spacing between the hubs and discs. They are commonly used in applications where space constraints are a concern.

- Floating Shaft Disc Couplings: Floating shaft disc couplings are designed for applications where there is a need to connect shafts that are not in the same plane. They can accommodate both angular and axial misalignment.

- High-Speed Disc Couplings: These couplings are specifically engineered to handle high rotational speeds while maintaining precise alignment and minimal vibration.

- Heavy-Duty Disc Couplings: Heavy-duty disc couplings are built to transmit extremely high levels of torque and are often used in demanding industrial applications.

- Customizable Disc Couplings: Some manufacturers offer customizable disc couplings that can be tailored to specific application requirements, such as material selection, size, and design parameters.

The choice of disc coupling type depends on factors such as the level of misalignment, torque transmission requirements, space constraints, and environmental conditions. Selecting the appropriate type ensures optimal performance and reliability in various machinery applications.

editor by CX 2023-10-10