Product Description

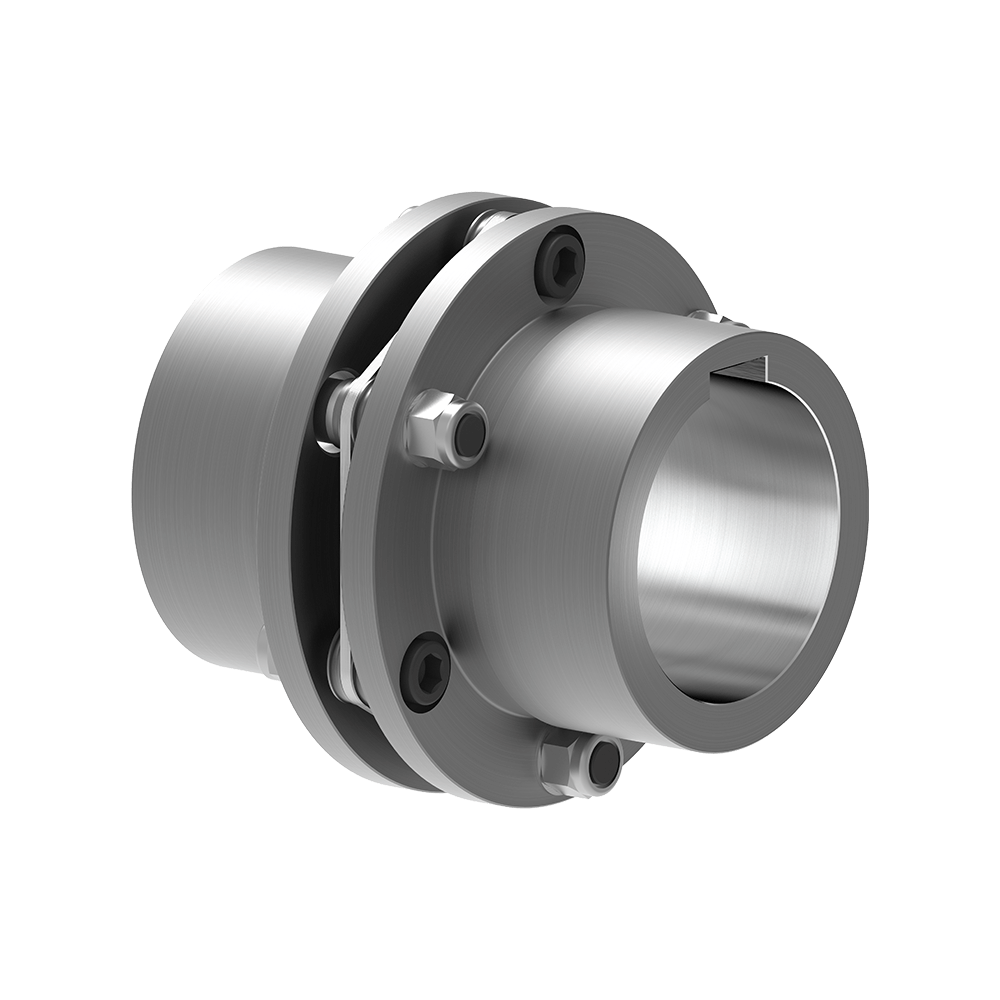

Stainless Steel Coupling Transmission Parts Gear High Quality Good Price Gear Roller Chain Couplings Nm Flange Flexible Elastomeric Stainless Steel Coupling

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality coupling.

1. Material: Cast iron, Rubber.

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing: Painted.

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

Fluid couplings:

Features:

Improve the starting capability of electric motor, protect motor against overloading, damp shock, load

fluctuation and torsional vibration, and balance and load distribution in case of multimotor drives.

Applications:

Belt conveyers, csraper conveyers, and conveyers of all kinds Bucket elevators, ball mills, hoisters, crushers,

excavators, mixers, straighteners, cranes, etc.

Flange Flexible Coupling:

Flexible Coupling Model is widely used for its compact designing,easy installation,convenientmaintenance,small size and

light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will

operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission

systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable

relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o 30′–1o 30′

Jaw Couplings:

Click here for more types of couplings

Our Services:

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

Company Information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Indicators of Wear or Damage in Disc Couplings

Disc couplings can exhibit signs of wear or damage over time due to factors like misalignment, overloading, or general usage. Detecting these issues early is crucial for preventing further damage. Some common indicators of wear or damage in disc couplings include:

- Vibration: Excessive vibration during operation can signal misalignment, component wear, or imbalance in the disc coupling.

- Noise: Unusual noises like clicking, clanking, or rattling can indicate wear, misalignment, or damage in the coupling components.

- Heat Generation: Excessive heat near the coupling area can suggest friction or misalignment issues.

- Reduced Performance: Decreased efficiency, torque transmission, or system performance may point to coupling wear or damage.

- Visual Inspection: Look for signs of visible wear, corrosion, cracks, or deformation on the coupling components.

To detect these signs of wear or damage, regular visual inspections, vibration analysis, and performance monitoring are essential. Early detection allows for timely maintenance or replacement of the affected components, ensuring the continued reliability and safety of the disc coupling and the machinery it serves.

Diagnosing and Troubleshooting Issues with Disc Couplings

Proper diagnosis and troubleshooting are essential to maintain the optimal performance of disc couplings within machinery systems. Here’s a step-by-step guide:

- Visual Inspection: Regularly inspect the disc coupling for signs of wear, damage, or misalignment. Look for disc fractures, corrosion, or unusual wear patterns.

- Noise and Vibration Analysis: Abnormal noise or excessive vibration could indicate misalignment, wear, or imbalance. Use vibration analysis tools to identify the source and severity of the issue.

- Torque and Load Monitoring: Monitor torque and load variations to detect abnormal fluctuations. Sudden changes could indicate issues with the coupling or connected components.

- Alignment Check: Verify that the coupling and shafts are properly aligned. Misalignment can lead to premature wear and reduced coupling performance.

- Temperature Analysis: Monitor the operating temperature of the coupling. Excessive heat can result from friction due to misalignment or insufficient lubrication.

- Lubrication Inspection: Ensure proper lubrication between the disc elements and hubs. Inadequate lubrication can lead to increased wear and reduced flexibility.

- Dynamic Testing: Perform dynamic tests to evaluate the coupling’s response to torque fluctuations and misalignment. Analyze the results for anomalies.

- Replacement of Worn Parts: If wear or damage is detected, replace worn disc elements, hubs, or other components as needed.

- Rebalancing: If vibration is an issue, consider rebalancing the connected components to reduce vibration and enhance overall system stability.

Regular monitoring and a proactive approach to addressing issues can help prevent costly downtime and ensure the longevity of the disc coupling and the machinery system as a whole.

Types of Disc Couplings for Specific Uses

Disc couplings come in various designs and configurations, each tailored to specific use cases and requirements. Here are some different types of disc couplings designed for specific applications:

- Single Disc Couplings: These couplings consist of two hubs and a single flexible disc element. They are suitable for applications where angular misalignment compensation is the primary requirement.

- Double Disc Couplings: These couplings include two flexible disc elements and three hubs. They provide higher torsional flexibility and axial movement absorption, making them suitable for more demanding applications.

- Spacer Disc Couplings: Spacer disc couplings incorporate a spacer between the flexible disc elements. This design allows for greater axial movement and misalignment compensation.

- Close-Coupled Disc Couplings: These couplings have a compact design with minimal spacing between the hubs and discs. They are commonly used in applications where space constraints are a concern.

- Floating Shaft Disc Couplings: Floating shaft disc couplings are designed for applications where there is a need to connect shafts that are not in the same plane. They can accommodate both angular and axial misalignment.

- High-Speed Disc Couplings: These couplings are specifically engineered to handle high rotational speeds while maintaining precise alignment and minimal vibration.

- Heavy-Duty Disc Couplings: Heavy-duty disc couplings are built to transmit extremely high levels of torque and are often used in demanding industrial applications.

- Customizable Disc Couplings: Some manufacturers offer customizable disc couplings that can be tailored to specific application requirements, such as material selection, size, and design parameters.

The choice of disc coupling type depends on factors such as the level of misalignment, torque transmission requirements, space constraints, and environmental conditions. Selecting the appropriate type ensures optimal performance and reliability in various machinery applications.

editor by CX 2024-04-29