Product Description

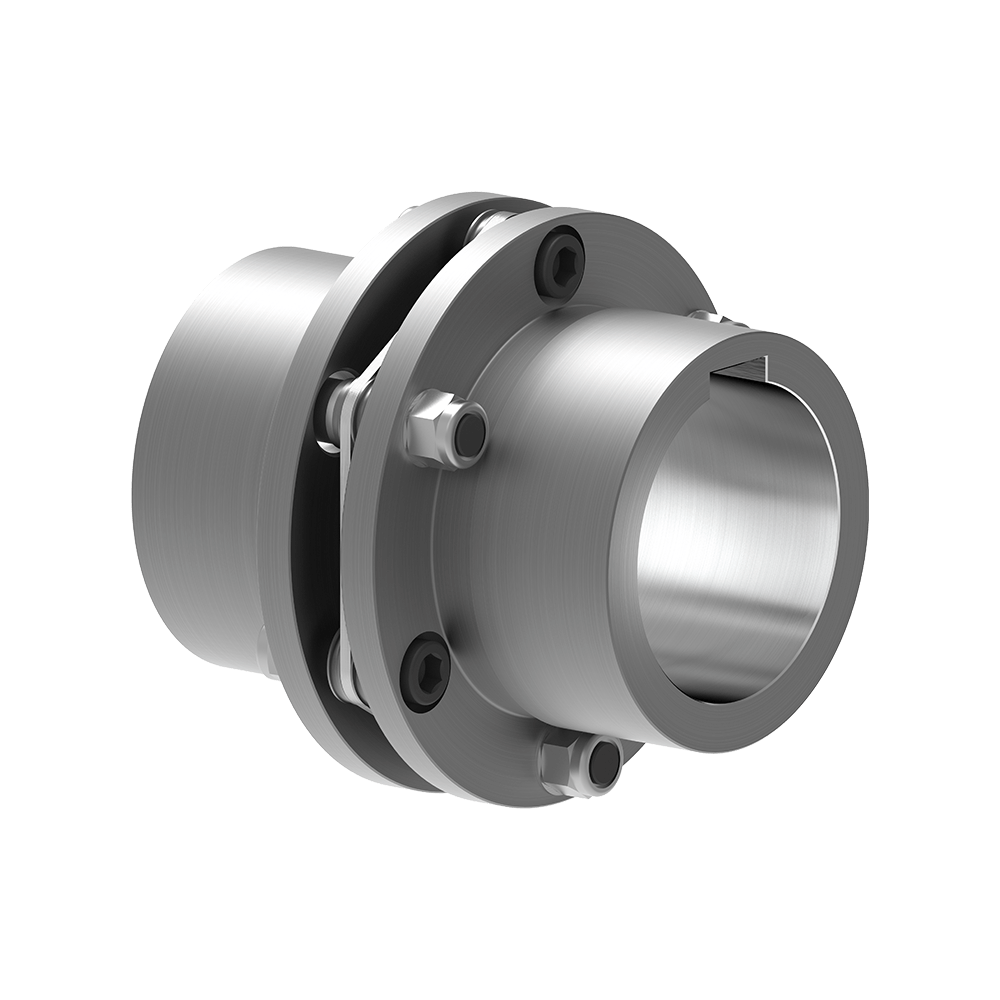

Double Diaphragm Coupling Aluminum Alloy Disc Coupling

Description:

The diaphragm is made of 304 stainless steel. The diaphragm coupling has a super shock absorption effect. It has no noise and no wear when used, so it will have a good use effect for the compensation machine, and it will play a good advantage in various harsh environments. It can adapt to the temperature difference between high and low temperatures, and can reach the service temperature of 80 ºC below zero and 300 ºC above zero, And under such a temperature state, its normal use effect will not be affected, and no performance change will occur.

1, Short Double diaphragm type flexible coupling

2, High torsional rigidity, no gap connection between shaft and shaft sleeve, suitable for ultra precision control

3, Common and servo, stepping motor

4, Clockwise and counterclockwise rotation characteristics are identical

5, Low inertia, suitable for high-speed operation

6, The diaphragm is made of 304 stainless steel, which can compensate radial, angular and axial deviations

7, In case of multiple deviations, the allowable value of a single deviation will be reduced

8, Double diaphragm type can absorb deflection and eccentricity, but the whole length will be longer.

Parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Indicators of Wear or Damage in Disc Couplings

Disc couplings can exhibit signs of wear or damage over time due to factors like misalignment, overloading, or general usage. Detecting these issues early is crucial for preventing further damage. Some common indicators of wear or damage in disc couplings include:

- Vibration: Excessive vibration during operation can signal misalignment, component wear, or imbalance in the disc coupling.

- Noise: Unusual noises like clicking, clanking, or rattling can indicate wear, misalignment, or damage in the coupling components.

- Heat Generation: Excessive heat near the coupling area can suggest friction or misalignment issues.

- Reduced Performance: Decreased efficiency, torque transmission, or system performance may point to coupling wear or damage.

- Visual Inspection: Look for signs of visible wear, corrosion, cracks, or deformation on the coupling components.

To detect these signs of wear or damage, regular visual inspections, vibration analysis, and performance monitoring are essential. Early detection allows for timely maintenance or replacement of the affected components, ensuring the continued reliability and safety of the disc coupling and the machinery it serves.

Impact of Number and Configuration of Disc Packs on Coupling Performance

The number and configuration of disc packs in a disc coupling have a significant impact on its overall performance. Here’s how:

- Number of Disc Packs: Increasing the number of disc packs can enhance the coupling’s torque capacity and stiffness. This allows it to handle higher levels of torque while maintaining its flexibility to accommodate misalignment.

- Configuration: Different configurations, such as single-flex, double-flex, or multiple-flex, offer varying degrees of angular misalignment compensation and torsional stiffness. Single-flex configurations provide greater misalignment capacity, while double-flex configurations offer improved torsional stiffness.

Choosing the appropriate number and configuration of disc packs depends on the specific application requirements:

- Torque Transmission: Applications with high torque demands may benefit from a higher number of disc packs to ensure reliable torque transmission.

- Misalignment Compensation: Applications with moderate misalignment may opt for configurations that offer higher angular misalignment compensation.

- Torsional Stiffness: For applications where torsional stiffness is critical, a configuration with multiple-disc packs may be preferred.

- Space Limitations: Consider the available space and coupling dimensions when choosing the number and configuration of disc packs.

- Dynamic Behavior: Depending on the application’s dynamic behavior and vibration characteristics, the appropriate configuration can be selected to minimize resonances.

Ultimately, the selection of the number and configuration of disc packs in a disc coupling should be based on a thorough understanding of the application’s torque, misalignment, and stiffness requirements to optimize coupling performance and reliability.

Challenges and Solutions for Misaligned Disc Couplings

Misalignment in disc couplings can lead to several challenges, but these issues can be effectively addressed using appropriate measures:

- Reduced Efficiency: Misalignment can cause increased friction and wear, leading to energy losses and reduced coupling efficiency. Regular maintenance and proper alignment can help mitigate this issue.

- Vibration and Noise: Misalignment often results in vibrations and noise in the machinery. This can impact the overall performance of the system and cause discomfort to operators. Ensuring precise alignment and using vibration-damping solutions can minimize these effects.

- Premature Wear: Disc couplings experiencing misalignment may wear out prematurely due to uneven loading and stress concentrations. Optimal alignment and using coupling models designed to handle misalignment can extend the coupling’s lifespan.

- Imbalanced Loads: Misalignment can lead to imbalanced loads on the coupling discs, causing uneven stress distribution. This can lead to fatigue and failure. Using spacer elements between the discs and proper alignment can distribute the loads more evenly.

- Reduced Accuracy: In applications requiring precision positioning, misaligned disc couplings can result in inaccurate measurements or positioning. Implementing accurate alignment practices and selecting couplings designed for precise applications can mitigate this challenge.

- Temperature Rise: Misalignment-induced friction generates heat, leading to temperature rise in the coupling and adjacent components. This can potentially affect the material properties and lead to premature wear. Proper alignment and selecting appropriate lubrication can manage temperature rise.

Addressing misalignment challenges involves a combination of careful installation, routine maintenance, alignment checks, and using coupling designs that offer flexibility and resilience to misalignment. Regular monitoring and addressing misalignment issues promptly can help ensure the longevity and optimal performance of disc couplings.

editor by CX 2024-02-19