Product Description

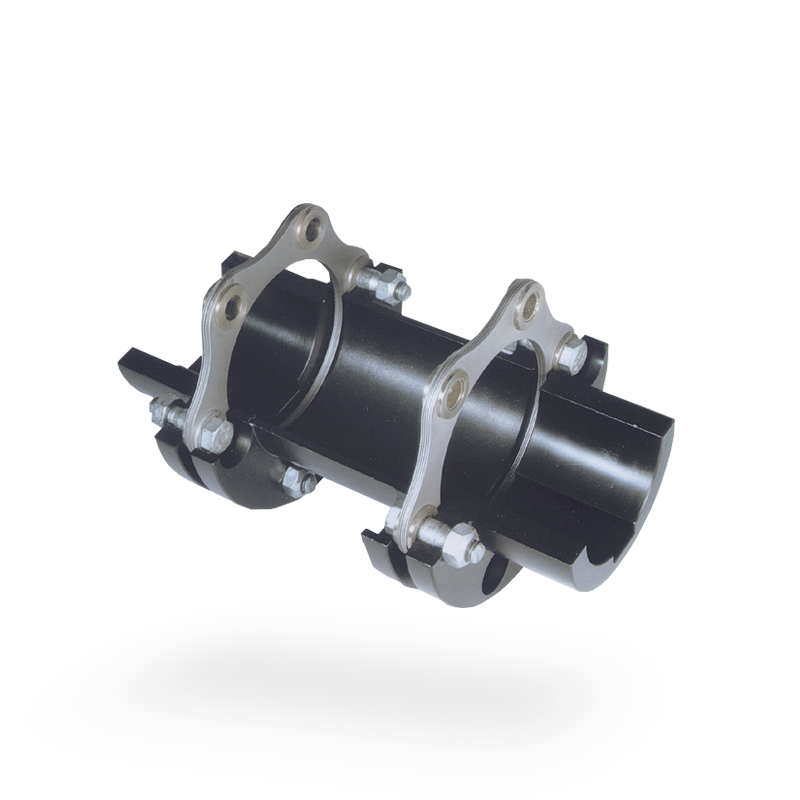

high pressure flexible coupling Flexible Disc Couplings

MODEL 77C STAINLESS STEEL HIGH PRESSURE FLEXIBLE COUPLING(SS-1200)

Sizes-Inches/DN

3/4 to 12inch(DN20 to DN300)

Rated working pressure:

1200 psi (83 bar) Sch. 40S, cut groove only

MODEL 77C MATERIAL SPECIFICATIONS

Housings:

Super duplex 2507 (CE3MN) to ASTM A890 Grade 5A

CE8MN to ASTM A890 Grade 2A

Duplex 2205(CD3MN)to ASTM A890 Grade 4A

Austenic 254SMO (CK3MCuN)to A743

Austenic 904L(CN2MCuN)to A351

Type 316 to ASTM A743 CF8M

Type 316L to ASTM A743 CF3M

Technical parameter:

| Product | coupling | |||

| Material | stainless steel 316,304; brass; aluminium; PP | |||

| Place of origin | china | |||

| Type | A / B / C / D / E / F / DC / DP / AA / DD / AD | |||

| Thread | NPT/BSP/BSPT/DIN2828. | |||

| Assembly parts | stainless steel, brass, aluminium handles, pins rings and safety pins |

|||

| Connection | male / female | |||

| Size | 1/2″-6″;DN15-DN150 | |||

| Gasket | buna(NBR),viton and teflon, silica | |||

| Test pressure | 3/4″-2″ 250PSI(17.6bar);3″-4″ 200PSI(14.8bar); 21/2″ 225PSI(15.8bar);6″150PSI(10.5bar) |

|||

| Workmanship | precision casting or forged | |||

| Application | petroleums,textiles,minings,brewings, inks, dyes, paper mills, processing plants |

|||

Packing:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Common Applications of Disc Couplings

Disc couplings find extensive use across various industries and applications where reliable torque transmission, misalignment compensation, and torsional stiffness are essential. Some notable examples include:

- Industrial Machinery: Disc couplings are employed in industrial equipment such as pumps, compressors, generators, and conveyors. They ensure precise torque transfer and alignment in heavy-duty machinery.

- Power Generation: Gas turbines, steam turbines, and power generators often utilize disc couplings to transmit torque between components while withstanding high rotational speeds.

- Aerospace: In aircraft and spacecraft, disc couplings help connect critical systems like engines and auxiliary power units, ensuring dependable torque transmission in demanding environments.

- Marine: Ships and offshore platforms use disc couplings to connect propulsion systems, generators, and other machinery, even in conditions with variable loads and misalignments.

- Oil and Gas: Disc couplings play a crucial role in drilling rigs, pumps, and other equipment where reliable torque transmission and misalignment compensation are vital.

- Automotive: Some automotive applications use disc couplings to connect components within drivetrains and transmissions, especially in vehicles with high-performance requirements.

These examples highlight the versatility and importance of disc couplings in various industries where precise torque transmission, misalignment handling, and torsional stiffness are critical for optimal performance.

Customization of Disc Couplings for Specific Machinery Requirements

Disc couplings can indeed be customized to match specific machinery requirements and limitations:

- Size and Configuration: Disc couplings can be tailored in terms of size and disc configuration to accommodate space restrictions and torsional load demands.

- Material Selection: The choice of materials for the disc packs can be customized to ensure compatibility with the operational environment, such as temperature, corrosion resistance, and other factors.

- Performance Parameters: Disc couplings can be designed to meet specific performance parameters, including torque capacity, misalignment accommodation, and torsional stiffness.

- Attachment and Hub Designs: The attachment mechanisms and hub designs can be customized to seamlessly integrate with the existing machinery components.

- Specialized Applications: Manufacturers can create disc couplings with unique features for specialized applications, such as those requiring higher precision, critical alignment, or specific levels of vibration dampening.

Through customization, disc couplings can effectively address the unique requirements and limitations of various machinery systems, enhancing their performance and reliability.

Design of Disc Couplings for Flexibility and Performance

The design of disc couplings plays a crucial role in providing flexibility and ensuring high-performance torque transmission. Key design elements include:

- Flexibility: Disc couplings consist of multiple thin metal discs arranged in a pack. These discs have slots or cuts that create segments, allowing them to flex and accommodate misalignment. The flexing action provides flexibility in multiple directions, allowing the coupling to handle angular, parallel, and axial misalignment.

- Torsional Stiffness: While providing flexibility, disc couplings also maintain a certain degree of torsional stiffness. This stiffness ensures efficient torque transmission between the shafts and helps maintain accurate positioning in precision applications.

- Material Selection: High-quality materials with appropriate mechanical properties are used to manufacture the discs. These materials must balance flexibility, torsional stiffness, and strength. Stainless steel and other alloys are commonly chosen for their durability and resilience.

- Geometry and Slot Patterns: The design of the slots or cuts in the discs influences the coupling’s flexibility and misalignment capabilities. Engineers optimize the geometry to provide the desired levels of flexibility and torsional stiffness.

- Spacer Elements: Some disc couplings include spacer elements between the discs. These spacers contribute to accurate alignment between the shafts and help prevent edge contact between the discs, reducing wear and enhancing durability.

- Balancing: Balancing the disc coupling reduces vibration and rotational imbalance. Precision machining and balancing techniques ensure that the coupling operates smoothly at various speeds, minimizing stress on the connected machinery.

- Anti-Flailing Designs: In the event of a disc failure, anti-flailing designs prevent the discs from dislodging and causing damage to surrounding equipment or posing a safety hazard.

The combination of these design aspects results in a disc coupling that can handle misalignment, transmit torque efficiently, dampen vibrations, and maintain its performance over a wide range of operating conditions. The flexible yet robust design makes disc couplings suitable for various industrial applications.

editor by CX 2024-02-16