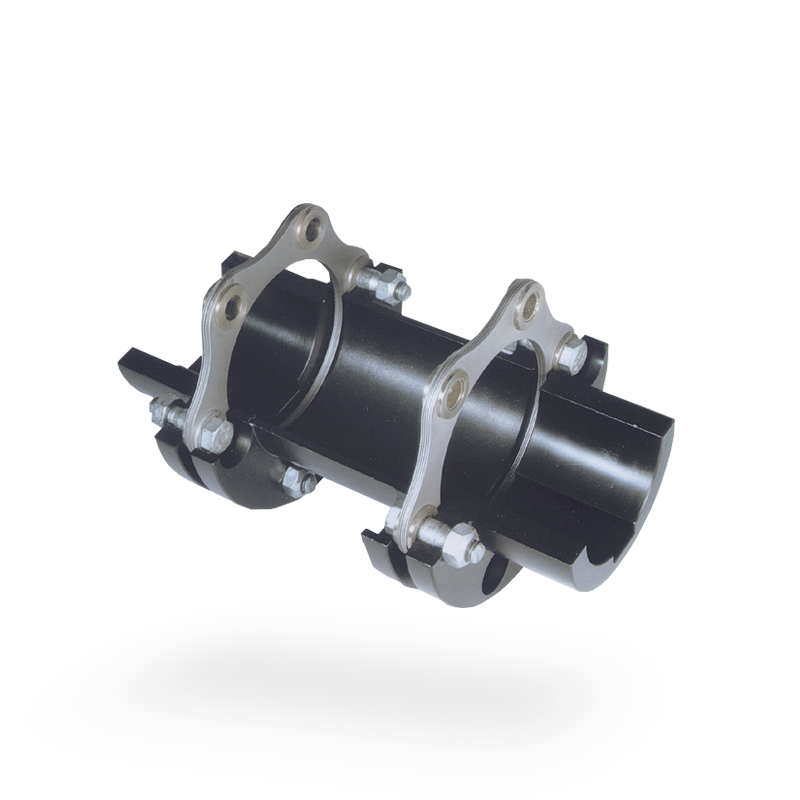

Product Description

| Item No. | φD | L | W | L1 | M | Tighten the strength(N.m) |

| SG7-8-C19- | 19.5 | 20 | 1.2 | 9.4 | M2.5 | 1 |

| SG7-8-C26- | 26 | 25.5 | 2.5 | 11.5 | M3 | 1.5 |

| SG7-8-C34- | 34 | 32.3 | 3.3 | 14.5 | M4 | 1.5 |

| SG7-8-C39- | 39 | 34.1 | 4.1 | 15 | M4 | 2.5 |

| SG7-8-C44- | 44 | 34.5 | 4.5 | 15 | M4 | 2.5 |

| SG7-8-C50- | 50 | 40.5 | 4.5 | 18 | M5 | 7 |

| SG7-8-C56- | 56 | 45 | 5 | 20 | M5 | 7 |

| SG7-8-C68- | 68 | 54 | 6 | 24 | M6 | 12 |

| SG7-8-C82- | 82 | 68 | 8 | 30 | M8 | 16 |

| SG7-8-C94- | 94 | 68 | 8 | 30 | M8 | 28 |

| SG7-8-C104- | 104 | 70 | 10 | 30 | M8 | 28 |

| Item No. | Rated torque | Maximum Torque | Max Speed | Inertia Moment | N.m rad | RRO | Tilting Tolerance | End-play | Weight:(g) |

| SG7-8-C19- | 1N.m | 2N.m | 10000prm | 0.65×10-6kg.m² | 200N.m/rad | 0.04mm | 1c | ±0.2mm | 12 |

| SG7-8-C26- | 1.4N.m | 2.8N.m | 10000prm | 1.8×10-6kg.m² | 690N.m/rad | 0.04mm | 1c | ±0.2mm | 31 |

| SG7-8-C34- | 2.8N.m | 5.6N.m | 10000prm | 7.2×10-6kg.m² | 1650N.m/rad | 0.04mm | 1c | ±0.2mm | 64 |

| SG7-8-C39- | 5.8N.m | 11.6N.m | 10000prm | 1.8×10-5kg.m² | 2500N.m/rad | 0.04mm | 1c | ±0.2mm | 97 |

| SG7-8-C44- | 8.7N.m | 17.4N.m | 10000prm | 2.5×10-5kg.m² | 2900N.m/rad | 0.04mm | 1c | ±0.2mm | 113 |

| SG7-8-C50- | 15N.m | 30N.m | 10000prm | 8.2×10-5kg.m² | 6700N.m/rad | 0.04mm | 1c | ±0.2mm | 195 |

| SG7-8-C56- | 25N.m | 50N.m | 10000prm | 1×10-4kg.m² | 8400N.m/rad | 0.04mm | 1c | ±0.2mm | 263 |

| SG7-8-C68- | 55N.m | 110N.m | 10000prm | 1.9×10-4kg.m² | 11500N.m/rad | 0.04mm | 1c | ±0.2mm | 445 |

| SG7-8-C82- | 80N.m | 160N.m | 10000prm | 7×10-4kg.m² | 14550N.m/rad | 0.04mm | 1c | ±0.2mm | 892 |

| SG7-8-C94- | 185N.m | 370N.m | 10000prm | 1.23×10-3kg.m² | 16900N.m/rad | 0.04mm | 1c | ±0.2mm | 950 |

| SG7-8-C104- | 255N.m | 510N.m | 10000prm | 1.86×10-3kg.m² | 25100N.m/rad | 0.04mm | 1c | ±0.2mm | 1190 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Disc Couplings

Disc couplings, like other mechanical components, are subject to various industry standards and guidelines that ensure their safe and reliable operation. Some relevant standards include:

- API Standard 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings for use in petroleum, chemical, and gas industry services. It covers the design, materials, testing, and inspection of couplings, including disc couplings.

- AGMA Standard 9001: The American Gear Manufacturers Association (AGMA) standard 9001 addresses flexible couplings, including disc couplings, and provides recommendations for their design, installation, and maintenance.

- ISO 14691: This International Organization for Standardization (ISO) standard covers general-purpose industrial couplings, including disc couplings, and provides guidance on their selection, installation, and operation.

Manufacturers and engineers often refer to these standards and guidelines to ensure that disc couplings are designed, manufactured, and used according to recognized industry practices. Adhering to these standards helps enhance the reliability, safety, and performance of disc couplings in various industrial applications.

Unique Construction of Disc Couplings for Vibration Dampening and Resonance Control

The distinctive construction of disc couplings plays a vital role in their ability to dampen vibrations and control resonance:

- Flexible Disc Packs: Disc couplings consist of multiple thin metal discs stacked alternately. These discs are connected to the hub and spacer, creating a flexible structure that can absorb and dissipate vibrations.

- Radial Compliance: The flexible discs allow for radial compliance, enabling the coupling to absorb misalignments and shocks, which helps prevent the transmission of vibrations.

- Torsional Flexibility: The flexible nature of the disc packs provides torsional flexibility, allowing the coupling to absorb torsional vibrations and shocks that may arise from the machinery.

- Resonance Damping: The design of disc couplings helps dampen resonant frequencies. The unique construction disperses energy across the flexible elements, reducing the risk of resonant vibration buildup.

- Material Selection: The choice of materials for the discs plays a role in controlling resonance. The right combination of material properties can help mitigate the effects of resonance.

By efficiently absorbing and dissipating vibrations and controlling resonance, disc couplings contribute to smoother operation, reduced wear and tear on machinery components, and enhanced overall system performance.

Design of Disc Couplings for Flexibility and Performance

The design of disc couplings plays a crucial role in providing flexibility and ensuring high-performance torque transmission. Key design elements include:

- Flexibility: Disc couplings consist of multiple thin metal discs arranged in a pack. These discs have slots or cuts that create segments, allowing them to flex and accommodate misalignment. The flexing action provides flexibility in multiple directions, allowing the coupling to handle angular, parallel, and axial misalignment.

- Torsional Stiffness: While providing flexibility, disc couplings also maintain a certain degree of torsional stiffness. This stiffness ensures efficient torque transmission between the shafts and helps maintain accurate positioning in precision applications.

- Material Selection: High-quality materials with appropriate mechanical properties are used to manufacture the discs. These materials must balance flexibility, torsional stiffness, and strength. Stainless steel and other alloys are commonly chosen for their durability and resilience.

- Geometry and Slot Patterns: The design of the slots or cuts in the discs influences the coupling’s flexibility and misalignment capabilities. Engineers optimize the geometry to provide the desired levels of flexibility and torsional stiffness.

- Spacer Elements: Some disc couplings include spacer elements between the discs. These spacers contribute to accurate alignment between the shafts and help prevent edge contact between the discs, reducing wear and enhancing durability.

- Balancing: Balancing the disc coupling reduces vibration and rotational imbalance. Precision machining and balancing techniques ensure that the coupling operates smoothly at various speeds, minimizing stress on the connected machinery.

- Anti-Flailing Designs: In the event of a disc failure, anti-flailing designs prevent the discs from dislodging and causing damage to surrounding equipment or posing a safety hazard.

The combination of these design aspects results in a disc coupling that can handle misalignment, transmit torque efficiently, dampen vibrations, and maintain its performance over a wide range of operating conditions. The flexible yet robust design makes disc couplings suitable for various industrial applications.

editor by CX 2023-12-26